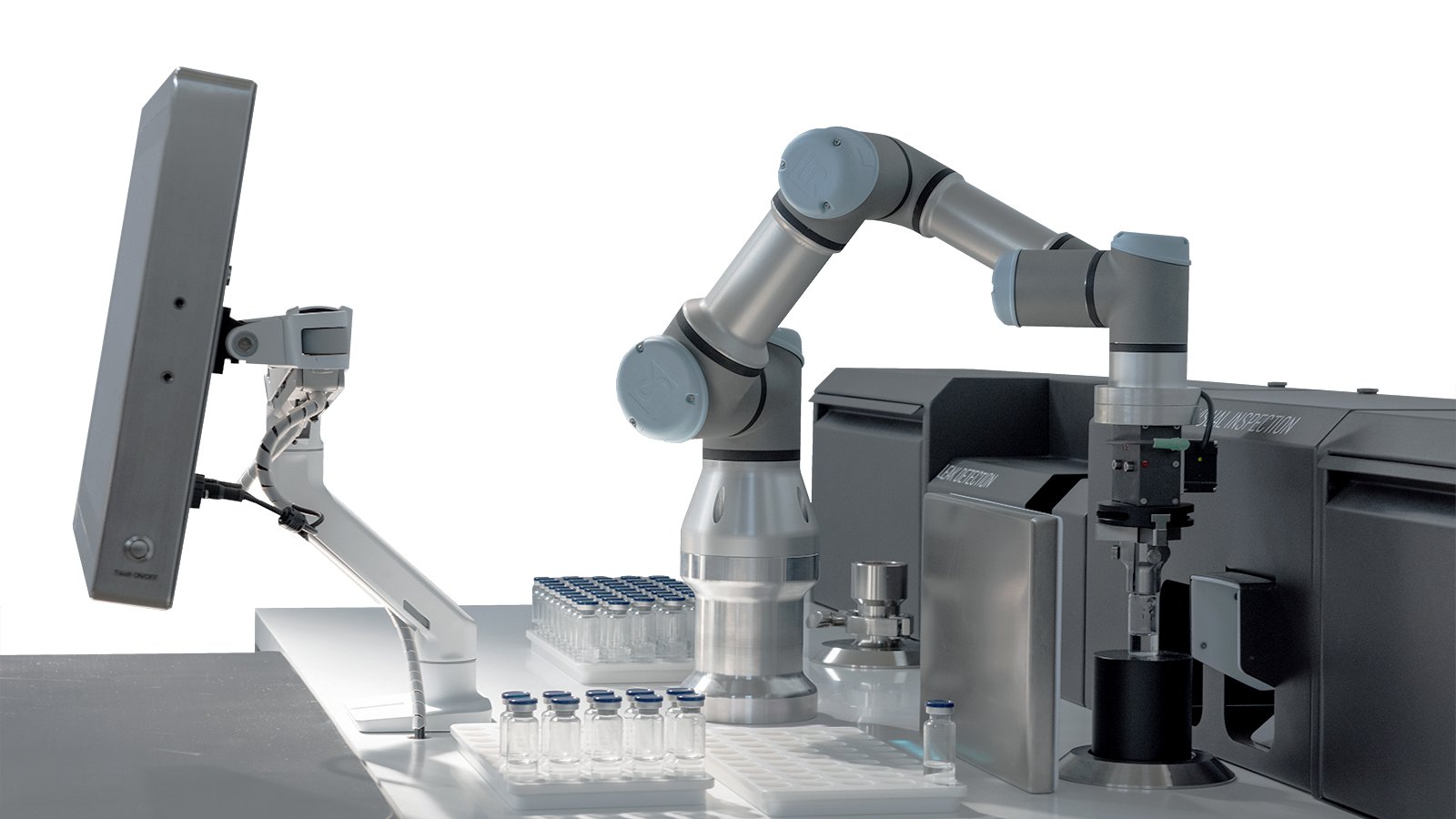

SAIL Smart Automated Inspection Laboratory

Pharmaceuticals

SAIL is an automated inspection laboratory for different container types, sizes, and contents bringing together CCIT, AVI and HGA all in one machine suitable for in-process, clinical trials and laboratory use.

PLAY VIDEO

Ampoules

BFS

Carpoules

Cartridges

Prefilled Syringes

Vials

Highlights

- All in one Industry 4.0 based laboratory

- Ergonomic workstation

- Scientific and objective inspection

- 100% traceability

- Time & cost saving