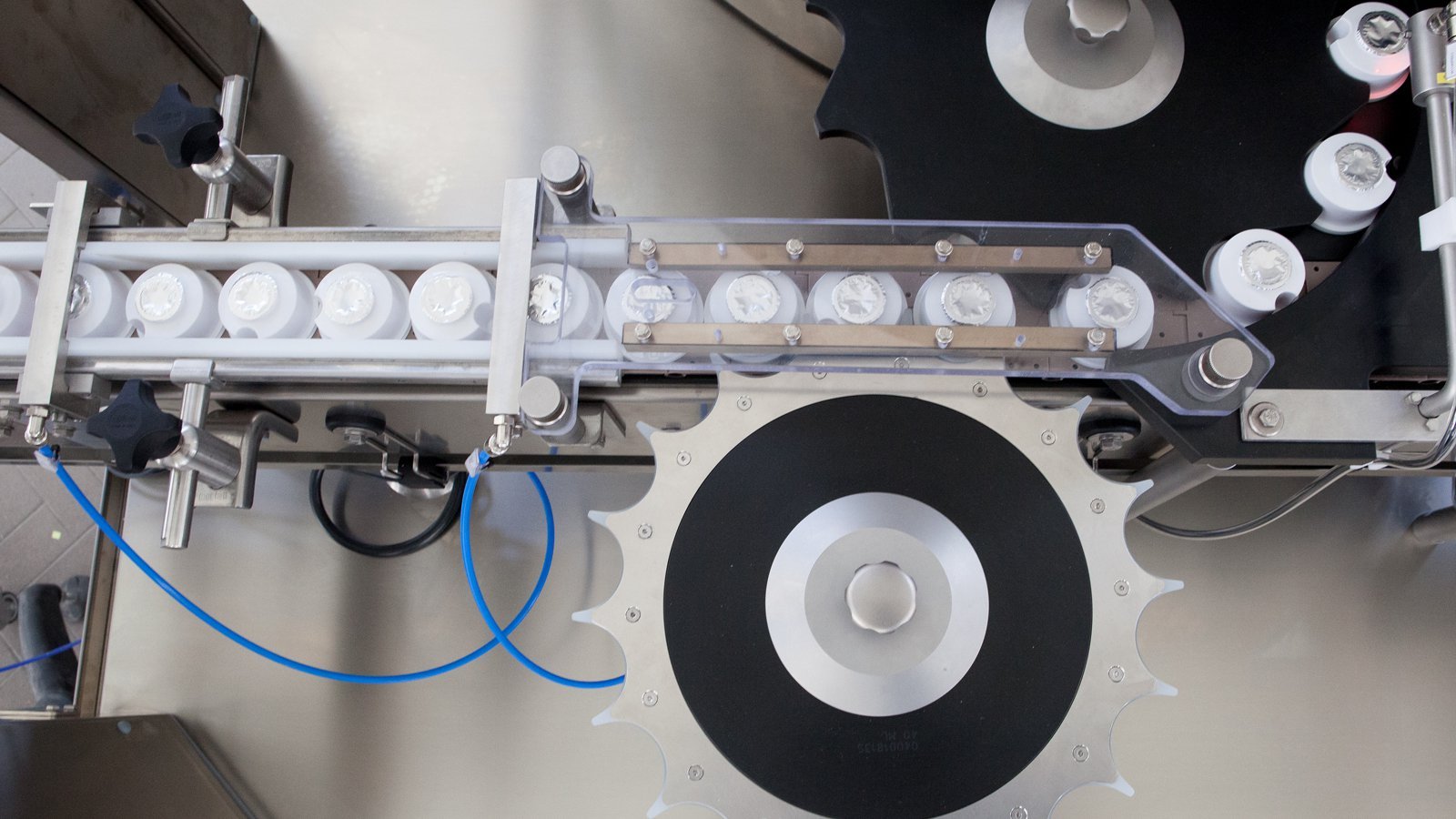

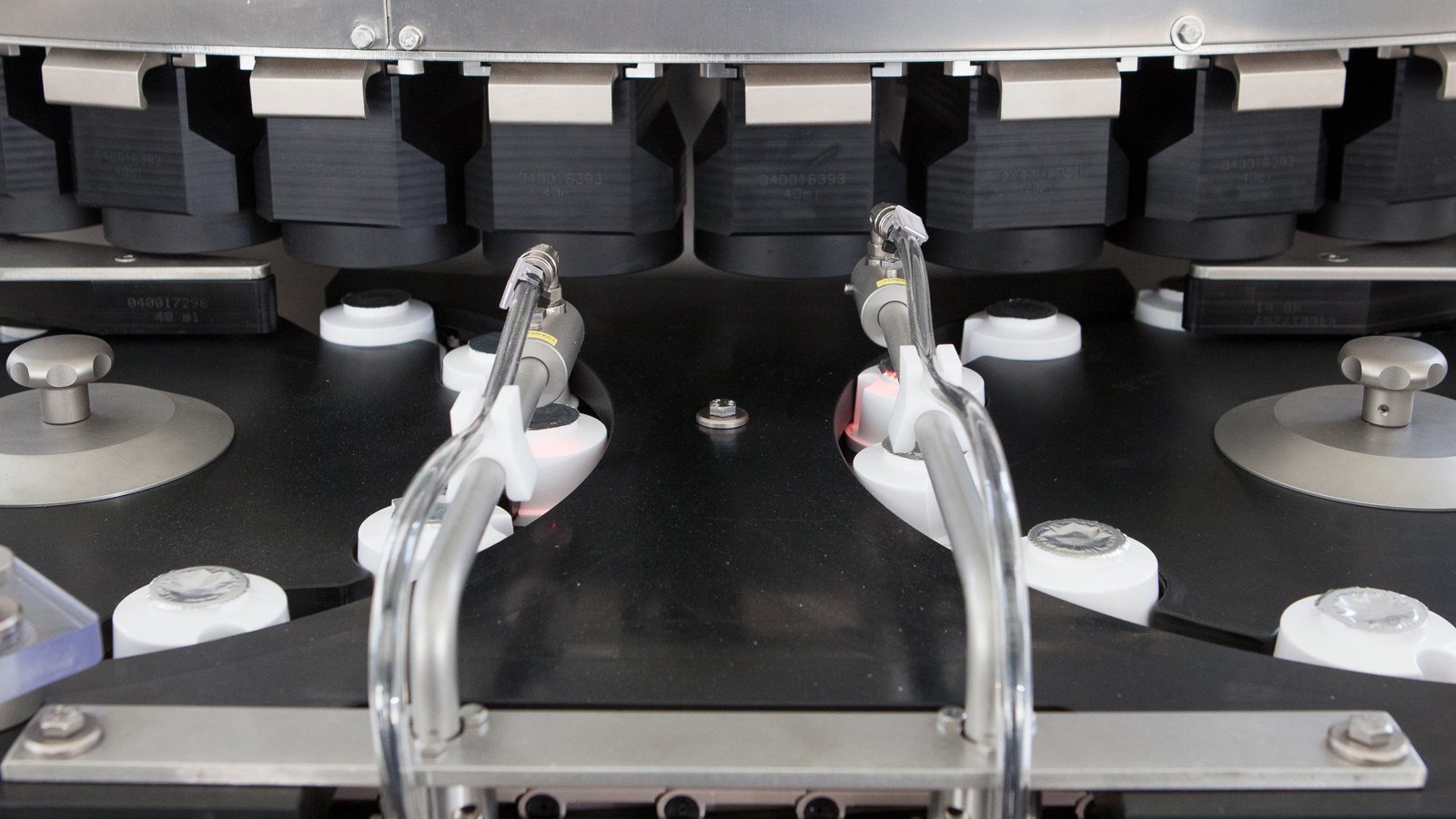

RLD 400 EC Leak Tester

Food & Beverages

100 % In-Line Machine for Non-Invasive, Non-Destructive Integrity Inspection for empty containers.

PLAY VIDEO

Bottles

Ready Meals

Cups

Food Trays

Highlights

- Zero downtime

- Zero alteration of container features

- Quality Ensured: No leaking containers due to: microholes, inappropriate sealing or cracks

- Safe products for the end-user & manufacturers protection from financial loss due to recalls, lawsuits and potential adverse publicity