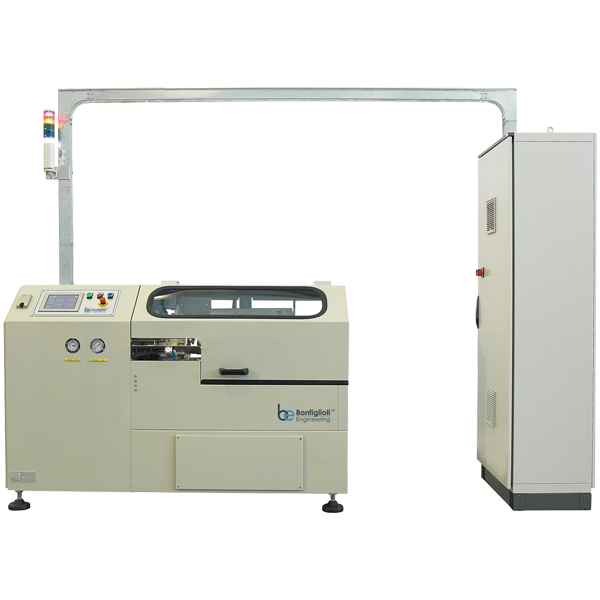

RLD 250 Leak Tester

Chemicals & Personal Care

100% In-line Machine for Non-Invasive, Non-Destructive Integrity Inspection at high production speed for empty containers (such as Plastic Tubes).

PLAY VIDEO

Tubes

Highlights

- Zero alteration of container features

- High machine adaptability & stability

- Easy management

- Low energy consumption

- Low & Ease of maintenance: free access to all moving parts

- Industry 4.0 Environment compliant