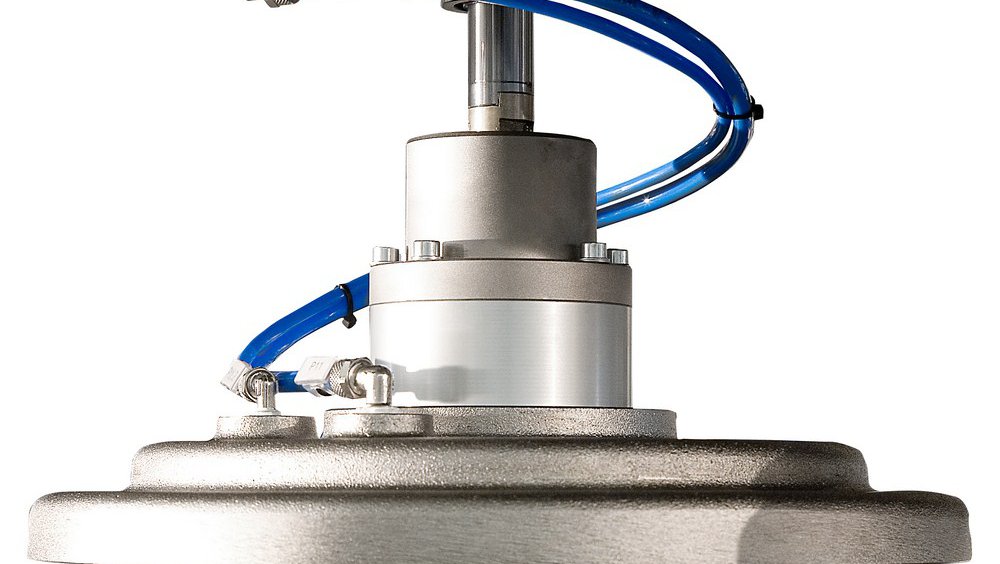

RLD 230S Leak Tester

100% In-line Machine for Non-Invasive, Non-Destructive Integrity Inspection at high production speed for empty containers (such as Pails, Drums, Composite Cans, 3 Pieces Cans, 2 Pieces Cans, Metal Canning).

PLAY VIDEO

Composite Can

2 Pieces Cans

Highlights

- Zero alteration of container features

- High machine adaptability & stability

- Easy management

- Low energy consumption

- Low & Ease of maintenance: free access to all moving parts

- Full integration in Industry 4.0 Environment