PK-VIS In-line Automatic Visual Inspection Tester

Pharmaceuticals

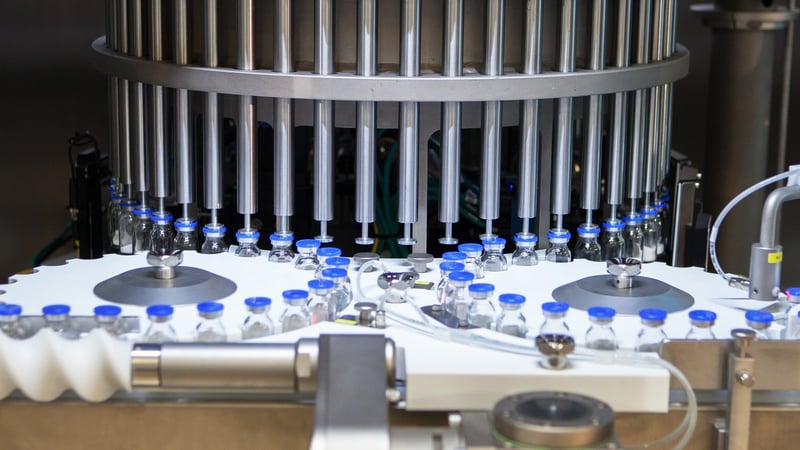

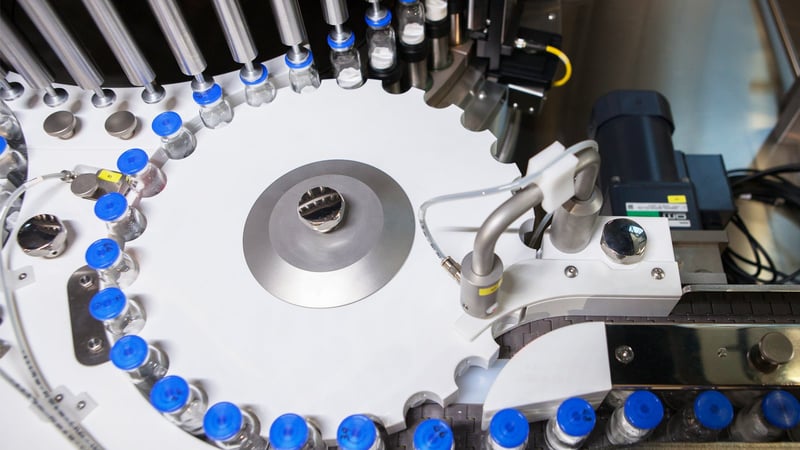

In-line and Off-line Non-Invasive, Non-Destructive Automatic Visual Inspection (AVI) System of containers with pharmaceutical product at high production speed

PLAY VIDEO

Ampoules

BFS

Bottles

Carpoules

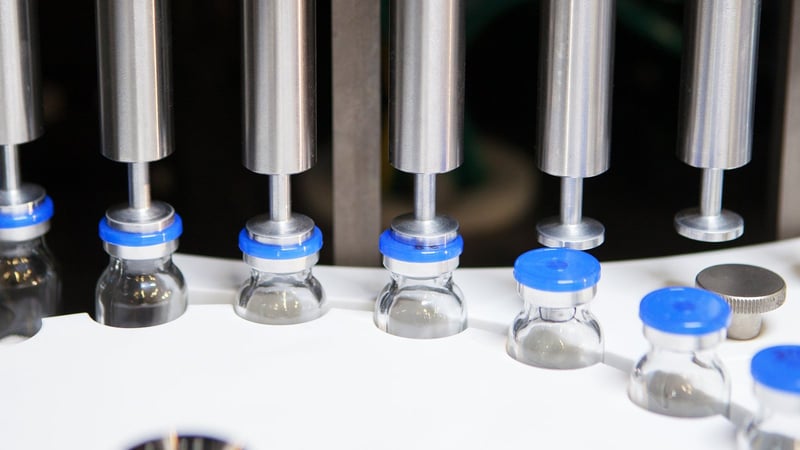

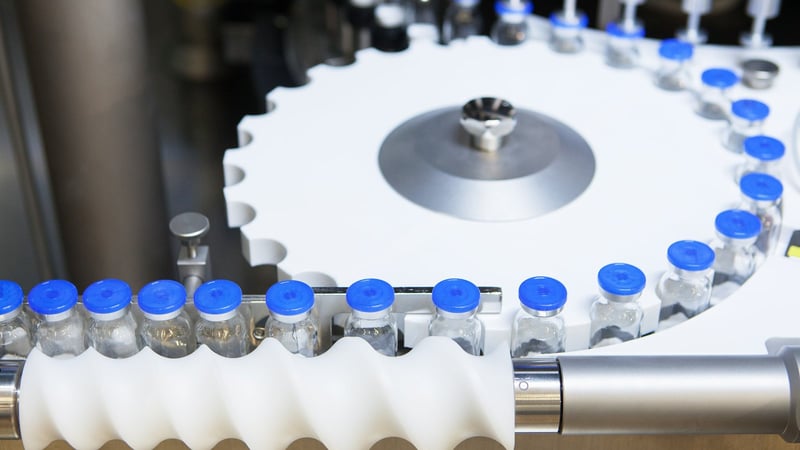

Vials

Highlights

- High inspection solutions flexibility

- High stability of application system and validation principles

- Hardware and Software optimization according to customer URS

- AVI no limited visual defects detection

- CFR part 11 compliance and 4.0 full integration