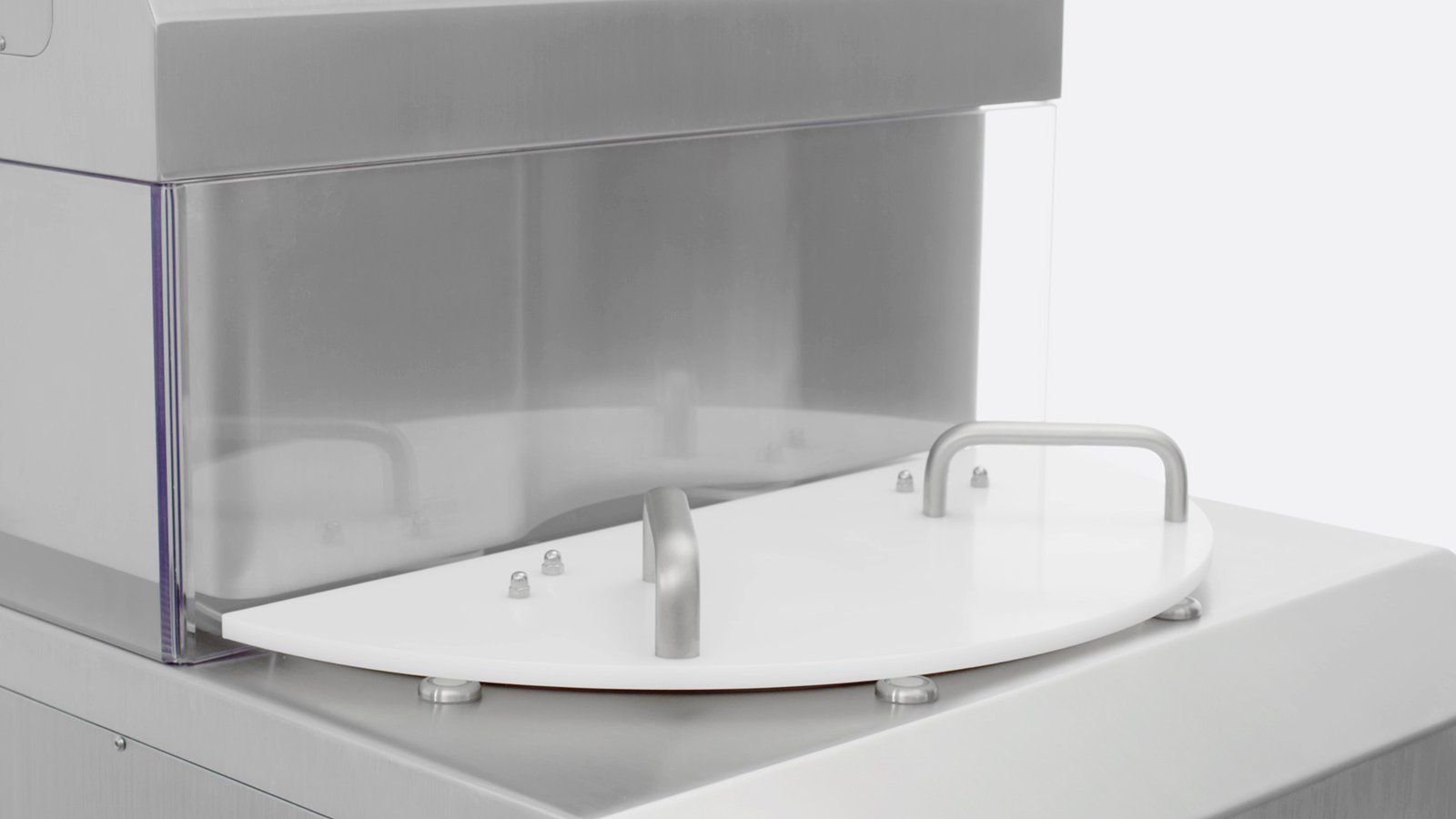

LF-SMH Lab scale multi-head CFR21 Part 11 Compliant

Food & Beverages

Non-Invasive, Non-destructive Integrity Inspection System for finished and filled containers for in process and off-line control applications.

PLAY VIDEO

Beverage

Doy Packs

Food

Ready Meals

Stick Packs

Highlights

- Quick and sensitive test

- Zero alteration of container features

- Vacuum

- Fast, reliable and repeatable results

- Highly functional, intuitive HMI

- Cost-effective solution

- System autodiagnostics available