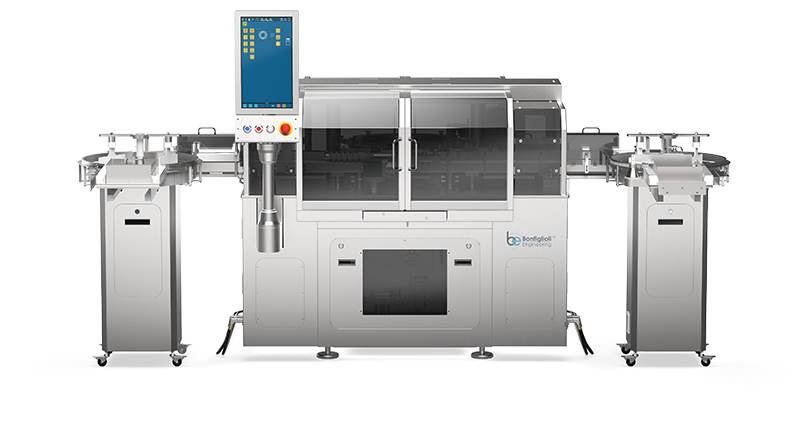

Laser EXP Headspace Gas Analyzer

Pharmaceuticals

A headspace gas analyzer designed and validated to demonstrate compliance with worldwide regulations. Uses a precise laser to perform 100%, non-invasive, non-destructive testing using TDLAS for quick, accurate, repeatable measurement of gas composition in the headspace of pharmaceutical products. Suitable for testing glass vials from 2R to 100R which contain liquid, powder, and lyophilized content.

Vials

Highlights

- Reliable, accurate CCIT results provide quality control of pharmaceutical products and process control of your production line

- Validation made easy, with complete documentation for effortless demonstration of regulatory compliance

- TDLAS test method delivers accurate, reliable, repeatable HGA results

- Efficient design optimizes production floor space without sacrificing capabilities