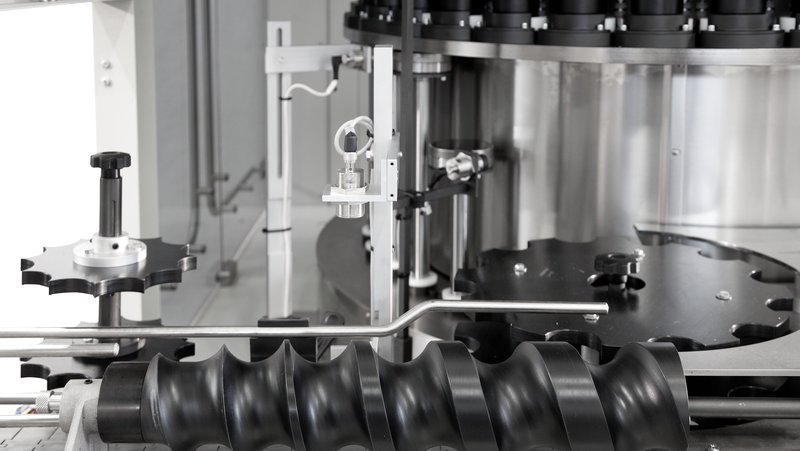

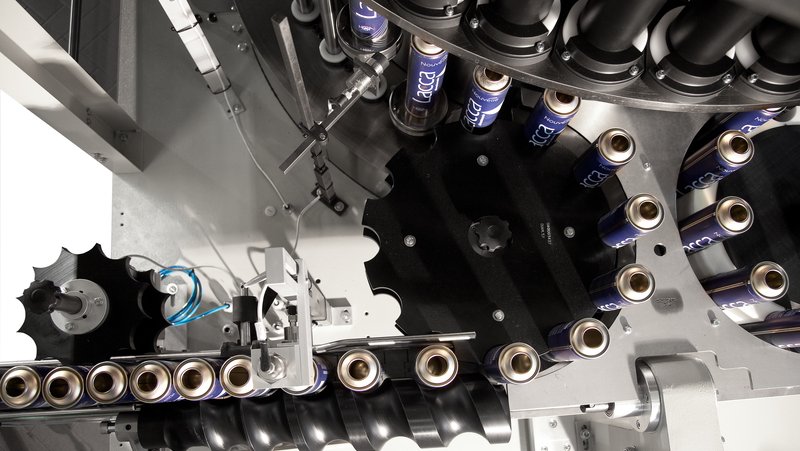

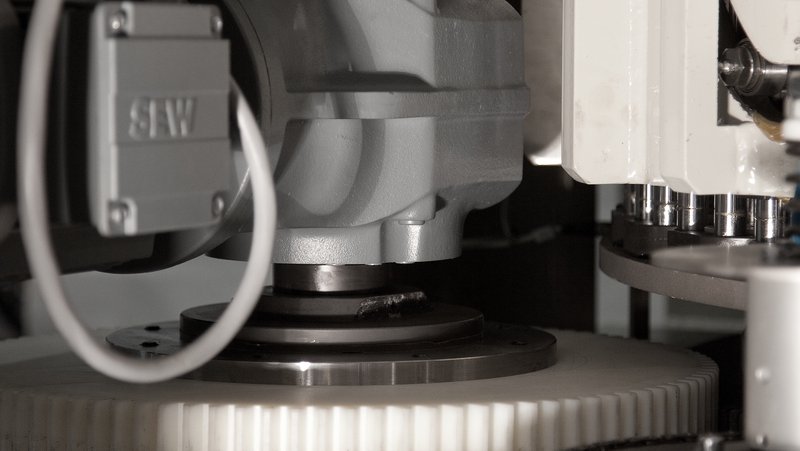

KBA Aerosol Leak and Pressure Tester

100% In-line Machine for Non-Invasive, Non-Destructive Integrity Inspection for empty aerosol cans.

PLAY VIDEO

Aerosol

Highlights

- Alternative test to water bath

- Zero downtime

- Total body integrity

- Zero alteration of container features

- High machine adaptability & stability