We are not just a machine manufacturer. We are your trusted partner for packaging integrity testing and analysis through feasibility studies, technical expertise, validation packages, product handling and custom-built solutions.

PDA Visual Inspection Forum

Date: 10 March - 11 March 2025

Location: Raleigh, North Carolina Marriott Crabtree Valley Hotel

Booth Number: #108

Our Speaker: Gianmarco Pincelli, Technical Sales Manager

Session Title: AI-Powered AVI: Image Classification Enhancement and False Rejection Rate Reduction in Blow-Fill-Seal DIPs

Explore how AI-powered Automated Visual Inspection is transforming BFS inspection, improving defect detection, reducing false rejects, and ensuring compliance with USP 1790 & Annex 1.

Bonfiglioli Engineering is honored to be a featured manufacturer exhibiting their high-performance pharmaceutical packaging inspection systems within the STEQ America booth at PDA Visual Inspection Forum.

Explore how AI-powered Automated Visual Inspection is transforming BFS inspection, improving defect detection, reducing false rejects, and ensuring compliance with USP 1790 & Annex 1.

Speaker Information: Gianmarco Pincelli, Technical Sales Manager, Bonfiglioli Engineering

With extensive experience in pharmaceutical packaging inspection, Gianmarco is at the forefront of helping to develop AI-driven automatic visual inspection solutions that enhance accuracy, reliability, and compliance in BFS and beyond.

Session Details: Optimizing Automatic Visual Inspection (AVI) for BFS Packaging

Pharmaceutical manufacturers face unique challenges in inspecting Blow-Fill-Seal (BFS) products, where issues like bubbles, wall thickness variation, and container shape inconsistencies make traditional visual inspection algorithms unreliable.

In this session, our industry-leading expert will discuss:

- How neural networks and machine learning improve AVI for BFS

- The impact of false reject rates (FRR) and how AI minimizes unnecessary waste

- The role of AI-driven inspection in regulatory compliance (USP 1790, Annex 1)

- Real-world applications: How AI improves bubble detection in BFS packaging

Whether you’re optimizing BFS inspection or facing challenges with other parenteral products, this session will provide practical insights and innovations that can enhance your production line’s accuracy and efficiency.

Join Us at PDA Vision Inspection Forum in Raleigh – Learn More

"Our goal is to help manufacturers achieve 100% inspection accuracy while reducing waste and operational inefficiencies. AI-driven AVI provides the quality assurance manufacturers want —and I look forward to sharing how it’s making a real impact.”

Gianmarco Pincelli

Technical Sales Manager

"We’re excited to share insights on how AI-powered AVI and innovative leak detection can optimize your production efficiency and compliance. Let’s connect." – Jesse Sklar, STEQ America

PDA Visual Inspection Forum Booth Details

We invite you to stop by booth #108 to meet with our experienced team and learn more about advancements in visual inspection technology that may support your needs.

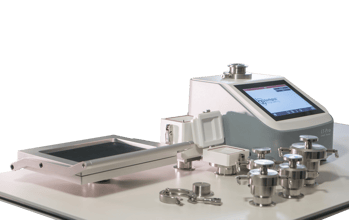

View and demo the LT-Pro Leak Tester, a flexible CCIT benchtop leak tester, ideal for laboratory and in-process control applications.

Learn more about our industry experience and meet with Gianmarco and Jesse Sklar from STEQ America.

Discuss the latest in leak detection, integrity testing, and AVI innovations.

Learn how to customize inspection systems to meet your production line’s needs.

LT-Pro Leak Detector: Non-destructive benchtop CCIT solution for laboratory and in-process control applications.

Not attending PDA Vision Inspection Forum? We can bring the insights to you!

If you’re exploring ways to improve AVI for BFS and other pharmaceutical packaging formats, schedule a 1:1 virtual consultation with our team.

Schedule a Virtual Consultation or Contact Us directly now info@bonfiglioliengineering.com